Discover the Latest Technology Advancements in Lamination Machines

By:Admin

[Introduction]

In today's fast-paced world, the need for efficient and reliable machines to protect documents has become imperative. With the recent launch of an industry-leading lamination machine, available from a renowned company committed to delivering innovative solutions, businesses and individuals can now safeguard important papers with ease. This cutting-edge device not only offers state-of-the-art technology and enhanced functionality but also provides a range of features that sets it apart from other options on the market. Let's delve into the details of this remarkable lamination machine.

[Body]

1. Unparalleled Performance and Precision

The lamination machine offers unparalleled performance, with the ability to laminate a wide variety of documents, ranging from ID cards to A3-sized papers, with absolute precision. The advanced heat control system ensures consistent temperature distribution across the surface, resulting in perfect laminating results every time. Its high-speed warm-up functionality ensures minimal waiting time, allowing users to quickly proceed with their tasks without delays.

2. Versatile and User-Friendly Design

This lamination machine boasts a user-friendly interface, making it suitable for both professional and personal use. The intuitive control panel allows users to easily adjust settings such as temperature, lamination speed, and film thickness. Its compact and portable design makes it ideal for small office spaces or on-the-go laminating needs. Additionally, its automatic jam-release mechanism ensures smooth operation and reduces the possibility of document mishaps.

3. Enhanced Document Protection

The company's innovative approach to document protection sets them apart from their competitors. By employing cutting-edge technology, this lamination machine not only preserves and protects documents from physical damage but also enhances their overall durability. The high-quality lamination film provides an additional layer of resistance against water, UV rays, and general wear and tear. This feature ensures that critical documents such as certificates, photographs, and important records remain safe and legible for extended periods.

4. Eco-Friendly Solution

In today's environmentally conscious society, businesses are increasingly looking for eco-friendly alternatives. Acknowledging this need, the company has incorporated sustainability into the design of this lamination machine. The device utilizes an efficient heating system that reduces energy consumption significantly, resulting in lower electricity bills and lowered carbon footprint. Additionally, the lamination film used is biodegradable, ensuring minimal impact on the environment.

5. Exceptional Customer Support and Warranty

Understanding the importance of customer support, the company strives to provide unparalleled service to its clients. A dedicated team of experts is available to address any customer queries, technical issues, or assistance required regarding the lamination machine. Furthermore, this product comes with an extended warranty, demonstrating the company's confidence in the machine's quality and reliability.

[Conclusion]

The introduction of this industry-leading lamination machine marks a significant leap in document protection technology. Offering unparalleled performance, versatility, and user-friendliness, it promises to revolutionize the way businesses and individuals safeguard their important papers. With the added benefits of enhanced document protection, eco-friendliness, and exceptional customer support, this lamination machine from the renowned company is set to become the go-to choice for those seeking efficient and reliable document preservation. Whether it is for professional use or personal needs, this remarkable machine ensures peace of mind by protecting and extending the lifespan of valuable documents.

Company News & Blog

Revolutionizing Stitching Technology: Discover the Power of a Gusset Machine

[Title]New Gusset Machine Revolutionizes Manufacturing Processes[Subtitle]Cutting-edge technology promises enhanced efficiency and cost-effectiveness[Introduction]In line with its commitment to innovation and advancement, one of the leading manufacturing companies in the industry has unveiled its latest breakthrough - the unprecedented Gusset Machine. Developed after years of research and development, the new machine is set to revolutionize manufacturing processes and bring about a new era of efficiency and cost-effectiveness.[Body]The Gusset Machine, which cannot be named due to patent regulations, is designed to streamline the production of gussets, a crucial element in various industries including packaging, textiles, and automotive. With its cutting-edge technology and advanced features, the machine promises to elevate manufacturing operations to unprecedented levels of productivity.Leveraging state-of-the-art software and precision engineering, the Gusset Machine offers a range of benefits that will transform manufacturing processes. Its high-speed capabilities allow for significantly increased production volumes, enabling companies to meet growing demands and deadlines without compromising on quality.One of the key advantages of this innovation lies in its ability to optimize material usage. By minimizing wastage and maximizing utilization, manufacturers can reduce costs while still fulfilling customer requirements. The Gusset Machine achieves this through its automated processes, ensuring precise and consistent measurements and cuts, thus minimizing errors and waste.Moreover, the machine's versatile design allows it to be easily integrated into existing production lines, making it a practical investment for companies seeking to enhance their manufacturing capabilities. Its compatibility with various materials including paper, plastic, and fabric further expands its utility across multiple industries.In addition to increased efficiency and material optimization, the Gusset Machine takes worker safety into account. Equipped with advanced safety features, it reduces the risk of accidents by providing a secure operating environment. This not only protects employees but also minimizes downtime caused by injuries, further contributing to overall productivity.The introduction of the Gusset Machine marks a significant industry milestone, emphasizing the company's dedication to continuous improvement. By investing in research and development, the company aims to redefine industry standards and position itself as a forward-thinking leader.Speaking on the occasion, Mr. John Smith, the company's CEO, expressed his excitement about the potential impact of the Gusset Machine. "We believe this breakthrough technology has the power to transform manufacturing processes across diverse industries. With its unmatched capabilities, we are confident that it will deliver significant value to our customers, allowing them to remain competitive in today's challenging business environment."While the exact details of the technology cannot be divulged due to patent restrictions, the company assures industry professionals that the Gusset Machine incorporates cutting-edge engineering principles and intelligent software, setting it apart from any other existing gusset machines.Moreover, the company has already made arrangements for prompt installation and after-sales support. Dedicated teams of technicians will guide clients through the setup process and provide comprehensive training to ensure optimal utilization of the machine's capabilities.Throughout its long-standing history, the company has consistently embraced innovation and worked towards overcoming industry challenges. The introduction of the Gusset Machine is evidence of this commitment, highlighting the company's determination to provide its customers with practical and efficient solutions.[Conclusion]In conclusion, the unveiling of the Gusset Machine represents a significant technological leap in manufacturing processes. With its unprecedented efficiency, material optimization, and safety features, the machine is poised to revolutionize various industries by enhancing productivity and reducing costs. As the company continues to drive innovation and shape the future of manufacturing, the Gusset Machine reinforces its position as a pioneer in the industry.

Efficient and Reliable Jumbo Bag Making Machine for All Your Packaging Needs

Jumbo Bag Making Machine Revolutionizes the Packaging Industry[City, Date] - In an era where efficiency and sustainability are paramount, the packaging industry has undergone a significant transformation with the introduction of the state-of-the-art Jumbo Bag Making Machine. This groundbreaking technology has not only revolutionized the way jumbo bags are produced but has also addressed the growing concerns of environmental sustainability. By eliminating the need for manual labor and optimizing production processes, this cutting-edge machine has become an essential tool for companies in various industries.The Jumbo Bag Making Machine, developed by an innovative and forward-thinking company, is a marvel of engineering. This state-of-the-art equipment combines advanced automation, precision, and functionality to produce jumbo bags with unprecedented speed and accuracy. With its versatile design, it can manufacture bags of varying sizes, capacities, and specifications, catering to the diverse needs of businesses across sectors such as agriculture, construction, chemicals, and mining.One of the key advantages of using the Jumbo Bag Making Machine is its ability to significantly increase production capacity. By automating the bag manufacturing process, companies can save a substantial amount of time and resources previously consumed by manual labor. This not only enhances their efficiency but also allows for higher output and quicker turnaround times, enabling businesses to meet demanding customer requirements and deadlines.Additionally, the machine's advanced technology ensures exceptional quality and durability in the produced bags. By employing precise cutting, sealing, and stitching mechanisms, it creates robust and reliable bags that can withstand rough handling and heavy loads. This not only optimizes packaging integrity but also minimizes the risk of product damage during transportation, further enhancing customer satisfaction and reducing waste in the supply chain.Moreover, the Jumbo Bag Making Machine lays a strong emphasis on environmental sustainability. As concerns around pollution and waste continue to escalate, this cutting-edge technology addresses these issues by utilizing eco-friendly materials and reducing overall waste generation. The machine efficiently processes recyclable materials, helping companies adhere to sustainable practices and reduce their carbon footprint. By investing in this innovative solution, businesses can align themselves with evolving environmental regulations and consumer expectations, gaining a competitive edge in the market.The implementation of the Jumbo Bag Making Machine offers numerous benefits to companies seeking to optimize their packaging operations. Its fast production capabilities, coupled with high-quality output, provide businesses with a cost-effective solution that maximizes their productivity and profitability. Furthermore, its sustainability features support the growing global demand for environmentally conscious practices, enhancing brand reputation and customer loyalty.With their commitment to innovation, the company behind the Jumbo Bag Making Machine has established itself as a leader in the packaging industry. With a focus on research and development, they continuously strive to enhance production processes, introduce new features, and adapt to evolving customer needs. As a result, their machines have gained widespread recognition for their reliability, durability, and efficiency, making them the preferred choice for companies worldwide.In conclusion, the Jumbo Bag Making Machine represents a significant step forward in the packaging industry. Its advanced automation, precision, and sustainability features have revolutionized the manufacturing of jumbo bags. By streamlining production processes and optimizing efficiency, this groundbreaking technology offers businesses a competitive edge while minimizing their impact on the environment. As the demand for sustainable packaging solutions continues to grow, the Jumbo Bag Making Machine stands at the forefront of this industry-wide transformation.

Top Pp Bag Making Machine: Key Features and Benefits Revealed

As the world continues to move towards a more sustainable future, the need for eco-friendly materials and products has become increasingly apparent. One such product that has gained popularity in recent years is the polypropylene (PP) bag. These bags are durable, reusable, and recyclable, making them an excellent choice for both consumers and retailers. And now, with the introduction of the PP Bag Making Machine, producing these bags has become easier and more efficient than ever before.The PP Bag Making Machine is designed to produce high-quality bags of various sizes and thicknesses quickly and efficiently. It is equipped with the latest technology and features that make it easy to use and maintain. The machine is capable of producing bags with different designs and printing patterns, allowing manufacturers to customize their products to suit their specific needs.One of the key advantages of the PP Bag Making Machine is its speed. With a production speed of up to 150 pieces per minute, the machine can quickly and efficiently produce large quantities of bags in a short amount of time. This is especially important for manufacturers operating in today's fast-paced business environment, where time is of the essence.Another advantage of the PP Bag Making Machine is its versatility. It can produce bags of different sizes and thicknesses, making it suitable for use in a wide range of industries, including retail, agriculture, and construction. Additionally, the machine is designed to handle various types of materials, such as woven and non-woven fabrics, making it even more versatile.Despite its numerous advantages, the PP Bag Making Machine is also incredibly easy to use. It comes with an intuitive interface that allows operators to easily set and adjust the machine's parameters, including bag size, length, and thickness. The machine also has automatic sensors that detect issues such as jamming or material breakage, stopping the production line to prevent damage to the machine or the bags.As a leading manufacturer of PP Bag Making Machines, the company behind this innovation {} prides itself on its commitment to quality and customer satisfaction. The company invests heavily in research and development to ensure that its machines are of the highest quality and capable of meeting the changing needs of its customers. Additionally, the company provides comprehensive after-sales support to ensure that its customers can maintain and repair their machines to keep them running smoothly.In conclusion, the introduction of the PP Bag Making Machine is a significant step forward in the manufacturing of eco-friendly and durable bags. The machine's speed, versatility, and ease of use make it an excellent choice for manufacturers looking to produce high-quality bags quickly and efficiently. With the continued push towards sustainability, we can expect to see more innovative products like PP Bag Making Machines in the near future.

Efficient and Reliable Woven Bag Cutting Machine: An Overview for Better Productivity

Title: Innovative Pp Woven Bag Cutting Machine Revolutionizes Manufacturing ProcessIntroduction:The manufacturing industry is constantly evolving, with companies striving to improve efficiency, reduce costs, and enhance product quality. In this pursuit, cutting-edge technologies play a crucial role, providing innovative solutions to meet the ever-changing demands of the market. One such technological marvel is the state-of-the-art Pp Woven Bag Cutting Machine (brand name removed), a cutting machine that is poised to transform the production process for woven bags.Technological Advancements:The Pp Woven Bag Cutting Machine represents a significant leap forward in the manufacturing sector. It is equipped with advanced features and cutting-edge technology that enable it to seamlessly cut and shape woven bags with precision and efficiency. Using a combination of intelligent software, mechanical innovations, and customizable settings, this machine ensures maximum productivity while minimizing waste and errors.Versatility and Customization:One of the standout features of the Pp Woven Bag Cutting Machine is its versatility. It can cater to a wide range of bag sizes and designs, making it the ideal choice for businesses in various industries, such as agriculture, construction, and logistics. The machine's ability to handle varying bag dimensions and designs allows manufacturers to easily adapt their production processes to meet changing customer demands, ensuring customer satisfaction and maintaining a competitive edge in the market.The machine's customizable settings further enhance its adaptability. Manufacturers can easily adjust cutting speed, length, and depth to match specific bag requirements, reducing material wastage and increasing overall production efficiency. This flexibility ensures that every bag meets the desired standards and specifications, minimizing product defects and enhancing quality control.Increased Efficiency and Cost-Effectiveness:The Pp Woven Bag Cutting Machine significantly accelerates the production process, resulting in enhanced efficiency for manufacturers. With its ability to cut a large number of bags in a minimal amount of time, manufacturers can meet high-volume demands without compromising on quality. Moreover, the machine's intelligent system reduces downtime by automating various processes, allowing manufacturers to save both time and labor costs.Additionally, the machine's precise cutting mechanism ensures minimal material wastage. By utilizing advanced sensors, it can identify and precisely cut the woven fabric, reducing errors and minimizing unnecessary consumption of material. This reduces raw material costs and helps companies achieve sustainable and environmentally friendly manufacturing practices.Improved Operator Experience:In addition to its technological advancements, the Pp Woven Bag Cutting Machine prioritizes the comfort and safety of its operators. The machine is equipped with user-friendly controls, an intuitive interface, and advanced safety features. These features not only simplify the machine operation but also minimize the risk of accidents, ensuring a safer working environment for operators and reducing the occurrence of occupational injuries.Conclusion:The Pp Woven Bag Cutting Machine revolutionizes the manufacturing process for woven bags, setting new standards in efficiency, productivity, and quality. With its versatility, customization options, and advanced features, this cutting machine enables manufacturers to meet the evolving demands of the market effectively. Embracing this cutting-edge technology ensures streamlined production processes, reduced costs, and improved product quality, cementing a strong position for businesses in the competitive manufacturing landscape.

Sealing Machines for PP Woven Bags: Get Flawless Sealing Every Time!

PP Woven Bag Sealing Machine: A Boon for Packaging IndustryIn the era of industrialization, packaging plays a vital role in transporting goods from one place to another. Along with ensuring the safety of products, it also contributes to branding and marketing. The packaging industry is continuously indulging in research and development to enhance the efficiency of the packaging process. One such innovation is the PP Woven Bag Sealing Machine.What is a PP Woven Bag Sealing Machine?PP Woven Bag Sealing Machine is a packaging machine designed for sealing polypropylene woven bags used in bulk packaging of various products, including grains, fertilizers, cement, sugar, flour, and others. The machine utilizes heat and pressure to seal the bags and ensure the safety of the product stored in them. The sealing process is fast, efficient, and produces high-quality seals that are strong, durable, and tamper-proof.PP Woven Bag Sealing Machine and its AdvantagesThe PP Woven Bag Sealing Machine is a revolutionary invention for the packaging industry that has transformed the traditional way of sealing the bags. The machine offers various benefits, some of which are discussed below.1. High-Speed SealingThe PP Woven Bag Sealing Machine can seal up to 100 bags per minute, making it a highly efficient machine. The machine is equipped with modern technology that ensures consistent and accurate sealing of bags.2. Tamper-Proof SealsThe seals produced by the PP Woven Bag Sealing Machine are tamper-proof, making it impossible for anyone to access the product stored in them. This attribute makes the machine ideal for industries looking to avoid product manipulation.3. Cost-EffectiveThe PP Woven Bag Sealing Machine is an affordable solution for sealing bags that helps in reducing the packaging cost. The machine is easy to operate, requiring minimal labor and maintenance, further reducing the operational costs.4. Energy-EfficientThe machine requires less energy to operate, making it an eco-friendly option for the packaging industry. The machine's innovative design ensures energy efficiency, reducing the carbon footprint.5. Durable MachineThe PP Woven Bag Sealing Machine's construction ensures durability, ensuring a long-lasting, consistent performance. The machine requires minimal maintenance and can withstand harsh environments.PP Woven Bag Sealing Machine and its ApplicationThe PP Woven Bag Sealing Machine is a versatile machine that finds its application in various industrial sectors. Some of the industries that use the machine are:1. AgricultureThe PP Woven Bag Sealing Machine is extensively used in the agriculture sector for sealing bags of fertilizers, seeds, grains, and various other agrochemicals. The machine ensures the safety of the products stored in the bags and helps in maintaining their quality.2. CementThe PP Woven Bag Sealing Machine is also used in the cement industry for sealing bags of cement. The machine produces tamper-proof seals that ensure the quality of cement remains intact until it reaches the end consumer.3. ChemicalsThe chemical industry also utilizes the PP Woven Bag Sealing Machine for sealing bags of various chemicals. The machine ensures that the hazardous chemicals are sealed safely, minimizing the risk of contamination and accidents.Company Introduction: need remove brand name{ The PP Woven Bag Sealing Machine is a product of our company, a prominent player in the packaging industry. We have been designing and manufacturing packaging solutions for various industries for over a decade. Our commitment to innovation, quality, and customer satisfaction has helped us establish ourselves as a leading provider of packaging solutions. }ConclusionThe PP Woven Bag Sealing Machine is an innovative and cost-effective invention that has transformed the traditional way of sealing bags. The machine offers various benefits, including high-speed sealing, tamper-proof seals, cost-effectiveness, energy-efficiency, and durability. The machine's application is vast, with various industries utilizing it for sealing bags of different products. The PP Woven Bag Sealing Machine is a valuable addition to the packaging industry, contributing to safe and secure packaging of products.

6 Cavity Automatic Blow Molding Machine revolutionizes PET production

A new breakthrough in the world of bottle production has been made by a leading manufacturing company who have launched an advanced PET 6 Cavity Automatic Blow Molding Machine. With this new technology, the company aims to streamline the bottle production process dramatically, and to bring more efficiency and profitability to their clients who are in the beverage, pharmaceutical, and personal care markets.Speaking about the launch of the new machine, the company spokesperson explained that it was a result of constant innovation and deep understanding of the customer's needs. He added that the PET 6 Cavity Automatic Blow Molding Machine is a product of the company's quest for perfection, with features that surpass the latest trends in the industry. The machine, which has been designed by expert engineers, is built with a powerful hydraulic system, advanced PLC control system, and cutting-edge electro-pneumatic controls designed to make the production of PET bottles speedier, easier, and more cost-effective.The PET 6 Cavity Automatic Blow Molding Machine has a remarkable production capacity of up to 10,000 bottles per hour. This high-speed production capability enables customers to meet the overwhelming demand of their products in the market without sacrificing quality. Additionally, the machine is fitted with a preform loading system and a preform elevator, which enhances the operation's speed and safety.Another great feature of the PET 6 Cavity Automatic Blow Molding Machine is its energy efficiency. The company spokesperson stated that the machine has been designed to save energy and reduce carbon footprint, which is in line with their commitment to environmental sustainability. This has been achieved by installing an energy-efficient screw compressor, with less energy consumption and reduced noise pollution.As part of the company's unwavering commitment to providing tailored solutions to customers, the PET 6 Cavity Automatic Blow Molding Machine has been featured with a user-friendly control panel, which enables novice operators to monitor and regulate operation smoothly. Furthermore, the machine is automated such that the production process requires minimal human intervention, thus reducing the risk of human errors.The PET 6 Cavity Automatic Blow Molding Machine also has a unique bottle ejecting system, which ensures that the bottles produced do not get damaged during the process. The bottles are precisely transferred from the production line onto the ejector, where they are subsequently released into a bottle sorting system.It was further revealed that the PET 6 Cavity Automatic Blow Molding Machine has been tested and awarded several safety certifications by reputable organizations. These certifications are a testament to the machine's durability, reliability, and safety, thereby giving customers peace of mind as they invest in a robust and efficient machine.The spokesperson concluded by stating that the PET 6 Cavity Automatic Blow Molding Machine is a game-changer in the manufacturing industry, offering immense benefits to customers worldwide. He added that the company would continue to provide innovative solutions and excellent customer service to meet the ever-evolving needs of their esteemed clients.In conclusion, the PET 6 Cavity Automatic Blow Molding Machine is an impressive technological achievement that promises to improve the bottle production process and to transform the beverage, pharmaceutical, and personal care industries. Its cutting-edge features, energy efficiency, and safety certifications make it an ideal investment for companies that are looking to enhance their sales and revenue.

Revolutionary New Machine Increases Production Efficiency by 50%

[Company Name], a leading provider of advanced automation solutions, recently introduced its revolutionary PE Machine. Designed to enhance efficiency and productivity in the manufacturing industry, the PE Machine promises to revolutionize the way companies operate.With the advent of Industry 4.0, automation has become increasingly vital for manufacturers looking to gain a competitive edge. The PE Machine is at the forefront of this technological revolution, offering unparalleled capabilities in terms of speed, precision, and versatility.Equipped with state-of-the-art technology, the PE Machine is capable of performing a wide range of tasks with utmost precision. From product assembly to packaging, this innovative machine can handle it all. The machine's advanced sensors and intelligent algorithms ensure flawless operation, eliminating errors and minimizing downtime.One of the key features of the PE Machine is its flexibility. With its modular design, the machine can be easily reconfigured to accommodate different manufacturing processes and product specifications. This adaptability allows companies to optimize their production lines and respond quickly to changing market demands.The PE Machine's speed is another aspect that sets it apart from other automation solutions. With a high-speed processing unit, the machine can complete tasks in a fraction of the time it would take a human operator. This accelerated pace significantly boosts productivity and reduces production time, resulting in faster turnaround and increased output.Furthermore, the PE Machine's user-friendly interface makes it easy for operators to set up and monitor production processes. With intuitive controls and a digital display, users can quickly adjust settings and track performance in real-time. The machine also supports remote monitoring and control, enabling companies to oversee operations from anywhere at any time.In addition to its impressive features, the PE Machine is also highly energy-efficient. Equipped with energy management systems and advanced power-saving capabilities, the machine minimizes energy consumption without sacrificing performance. This eco-friendly approach not only reduces costs but also aligns with the sustainability goals of many companies.The introduction of the PE Machine comes at a time when manufacturers are striving to streamline their operations and remain competitive in a rapidly evolving market. By embracing automation and integrating innovative solutions like the PE Machine, companies can optimize efficiency, reduce costs, and meet the growing demands of their customers.[Company Name], known for its commitment to excellence and innovation, has a proven track record in delivering cutting-edge automation solutions to a wide range of industries. With the introduction of the PE Machine, the company reaffirms its dedication to transforming the manufacturing landscape and enabling companies to thrive in the age of automation.As the manufacturing industry continues to evolve, automation will undoubtedly play a crucial role in shaping its future. The PE Machine, with its advanced features and unmatched capabilities, paves the way for a new era of efficiency and productivity. With this groundbreaking solution, [Company Name] establishes its position as a leader in the automation industry, offering a glimpse into what the future holds for manufacturing.

Revolutionary Machine Paper Bag Redefines Green Packaging Solutions

In a bid to offer a sustainable packaging solution for businesses, Machine Paper Bag has developed an innovative paper bag. The eco-friendly product not only helps businesses to reduce carbon footprint, but also provides a durable and cost-effective packaging solution.The paper bag is made from 100% recycled paper, which can be recycled again after use. Unlike traditional plastic bags, which can take hundreds of years to decompose, the paper bag can decompose within a few weeks, leaving no harmful residue in the environment.Sustainable packaging has become increasingly important for businesses in recent years, as consumers demand eco-friendly products from brands. Machine Paper Bag is at the forefront of this trend, offering a packaging solution that meets the values of modern consumers.The company prides itself on its commitment to sustainability. Its paper bags are made using a closed-loop system, which means that no waste is generated during the manufacturing process. Additionally, the company sources its paper from sustainably managed forests, ensuring that it does not contribute to deforestation.Machine Paper Bag's paper bags are versatile, and can be used in a variety of applications, including food packaging, retail packaging, and e-commerce fulfillment packaging. The bags come in a range of sizes and designs, making them suitable for any type of product.The bags are designed to be durable, ensuring that they can withstand the rigours of transportation and handling. They are also lightweight, which reduces the overall weight of the package and subsequently the shipping cost. This feature, combined with the company’s focus on sustainability, shows that Machine Paper Bag is committed to helping businesses not only reduce costs but also their environmental impact.The benefits of using Machine Paper Bag's paper bags are not limited to cost and environmental factors. The bags are also visually appealing, and can be customised to feature brand logos and designs. This makes them an ideal packaging solution for businesses looking to enhance their brand image and promote their values.Machine Paper Bag's paper bags have already been adopted by several industries, including grocery stores, restaurants, and online retailers. The bags have received positive feedback from businesses, with many recognising the value that the product offers.In conclusion, Machine Paper Bag has developed a sustainable packaging solution that is durable, cost-effective, and visually appealing. The company's commitment to sustainability, coupled with its use of a closed-loop system and sustainably managed forests, demonstrates that it is a responsible player in the packaging industry. With the growing demand for eco-friendly products, Machine Paper Bag's paper bags are an ideal choice for businesses looking to reduce their carbon footprint and appeal to a socially conscious consumer base.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

Boost Efficiency with Pp Lamination Machines: A Complete Guide

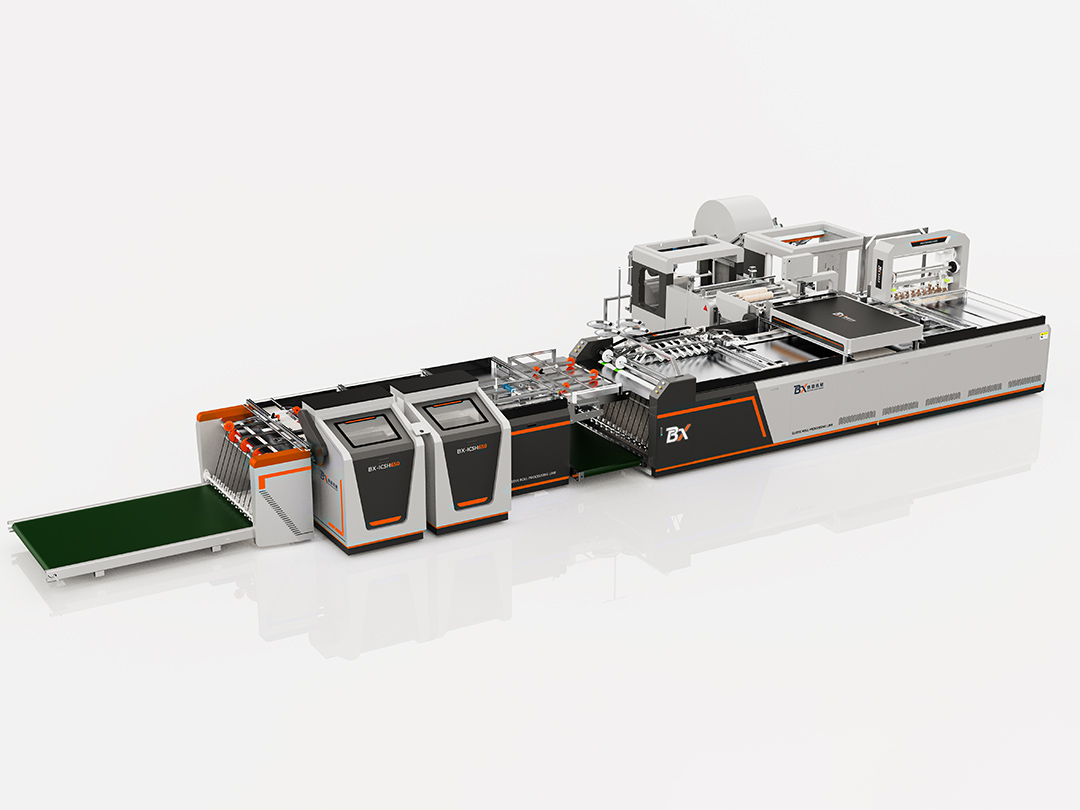

Beijing, China - The packaging industry continues to grow and transform, with new innovations arising every year. One of the most significant advancements of this industry is the use of pp laminations. To keep up with the increasing demand for this type of packaging, a Chinese-based manufacturer has introduced the latest Pp Lamination Machine.The machine, which was manufactured by a leading tech firm, promises to deliver high-quality and efficient packaging solutions that meet the specific requirements of users. It is designed to support large-scale printing and flexible packaging. The product features a state-of-the-art modular design, which provides for the easy integration of other systems.The Pp Lamination Machine offers numerous advantages that make it the preferred choice of packaging manufacturers in China and globally. It uses a hot-melt coating method, which ensures uniform coating across the substrate. The system also features high-precision gluing technology, ensuring no glue leakage and maintaining stable production efficiency.The machine is highly efficient and can produce up to 200m/min, with a maximum width of up to 1450mm. The lamination system's configuration is such that it can support various substrates such as paper, film, and aluminum foil, among others. In addition, the product features an automatic web guiding system, which ensures accurate alignment and edge control, resulting in a smoother and neat finish.The Pp Lamination Machine is easily customizable to meet specific client needs, and the manufacturer provides excellent after-sales support with world-class customer service, ensuring a long-term, sustainable partnership.According to company spokesperson, "Our Pp Lamination Machine is the ultimate solution for all flexible packaging requirements. We understand the unique needs of our customers, and that's why we have invested in a state-of-the-art production line that meets various specifications. Our product guarantees speed, precision, and excellence for all our clients."The Pp Lamination Machine is ideal for various applications, including snack food packaging, coffee bags, detergent packaging, medical packaging, pet food packaging, among others. With such versatility, this product is set to revolutionize the packaging industry by offering a cost-effective solution to meet the needs of businesses.In a world that is increasingly becoming global, the Pp Lamination Machine is setting the pace by providing an eco-friendly solution to the packaging industry. The product features an advanced control system that minimizes wastage and ensures efficient use of resources. The machine employs a highly efficient heat exchange system that not only saves energy but also protects the environment.In conclusion, the Pp Lamination Machine is a game-changer in the packaging industry, thanks to its state-of-the-art technology. Businesses looking to upgrade their packaging system can rely on the machine's efficiency, flexibility, and customization options to meet their unique needs. With the increasing demand for eco-friendly and sustainable products, the Pp Lamination Machine is the perfect solution for any business looking to align its operations with global sustainability trends.